Semiconductor Industry & Application

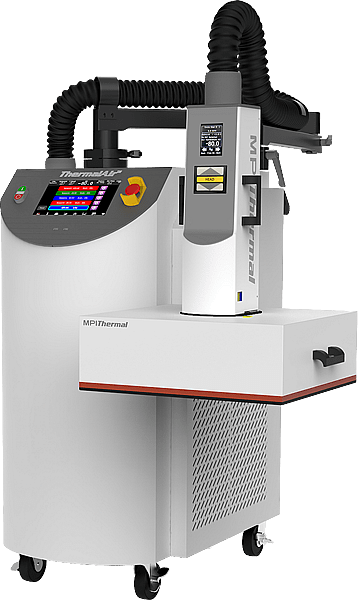

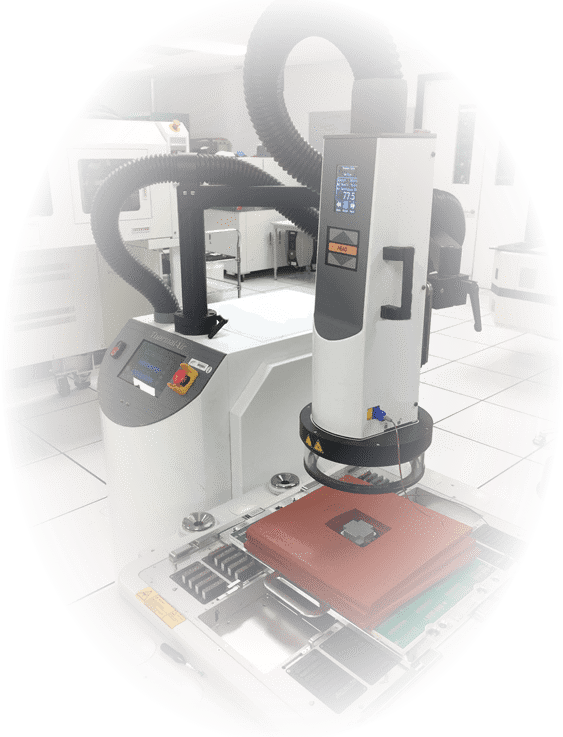

In semiconductor manufacturing, engineers design integrated circuits IC devices with temperature in mind. MPI Thermal systems are used in the semiconductor manufacturing process from product development in the product engineering labs to final assembly & test on the production floor.

-80°C / +225°C

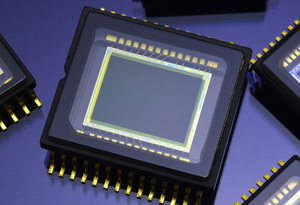

In the manufacturing of semiconductors electronic components for harsh environments, the IC package assembly and test stages of engineering and production include burn-in, electronic hot and cold testing at temperature, and other environmental test simulations. These semiconductor devices and electronics, once put in real world applications, can get exposed to extreme environmental conditions.

Product engineers and test engineers in the lab and on the semiconductor production floor use and share the ThermalAir temperature forcing systems to bring their devices to temperature ranges from -55°C to +125°C. ThermalAir environmental temperature test systems generate a hot and cold air stream directly on the device under test (DUT).

The ThermalAir TA-5000A has a temperature testing range from -80°C to +225°C without the use of LN2 or CO2. Our portable self-contained thermal inducing systems only need to be plugged in. This lets you easily temperature test your electronic semiconductor IC devices.

Download the DataSheets

Environmental Stress Testing

Environmental stress conditions such as radiation exposure, temperature extremes, vibration, and dirt encountered by the military, on factory floors, and under the hoods of automobiles, these semiconductor devices need to keep working. To assure quality and reliability of electronic devices, semiconductor manufacturers need to simulate harsh environments during the engineering and production test stage. This is why the MPI Thermal TA-5000 Series ThermalAir temperature test products are part of the test.

Thermal Test Semiconductor – Temperature Cycling Test – Temperature Testing Chamber – Thermal Test Equipment – Test ICs

Temperature Forcing System

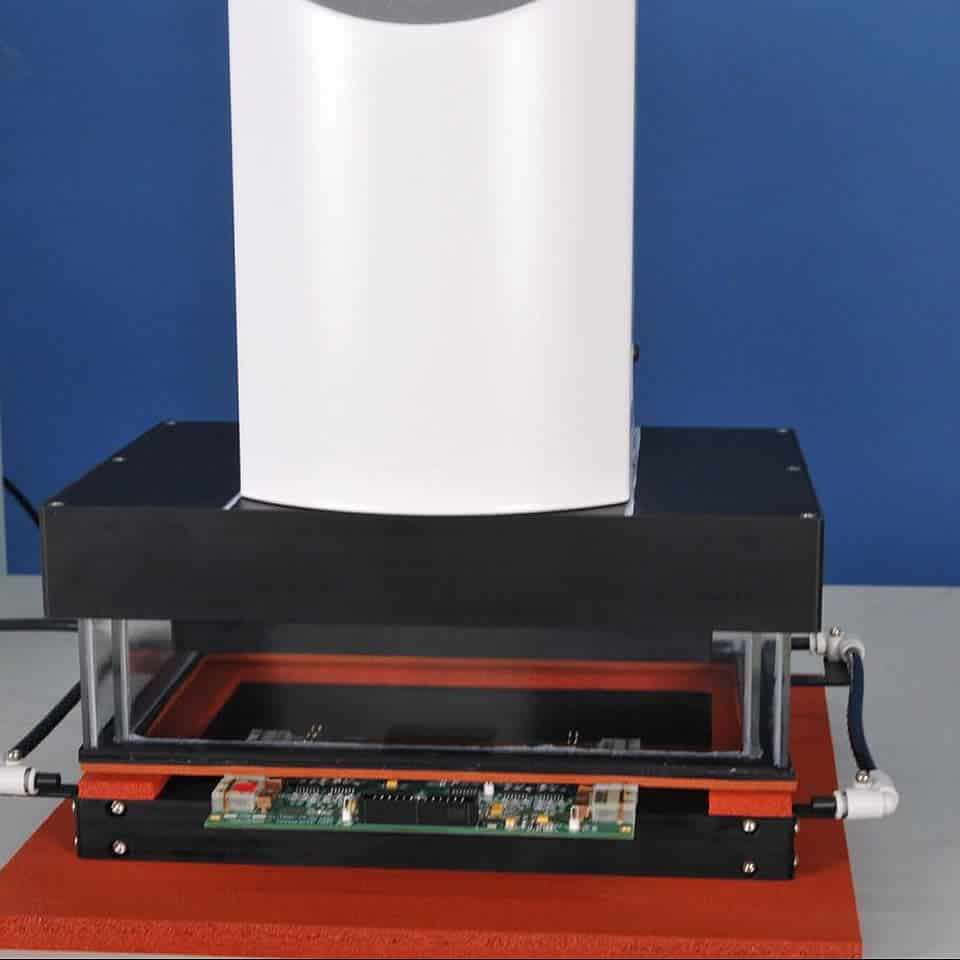

Precision Temperature Forcing Systems use a direct temperature-controlled stream of hot or cold air to provide a precise thermal environment for temperature testing, conditioning and cycling of electronic and non-electronic assemblies and sub-systems. The ThermalAir Temperature System enables the test. This allows you to perform temperature simulation tests in situ, at a specific location, at your tester station, test bench or directly on the unit under test.

Bring temperature to your test for Semiconductor IC devices and other semiconductor packages. ThermalAir forcing systems are used for semiconductor devices from Consumer Electronics to Aerospace and Defense applications ( mil aero MIL-STD 883 ) temperature range of -55°C to +125°C.

Some Thermal Test Applications

- Product Engineering

- Back-End Test

- Package Test

- Incoming Inspection

- IC Handler Verification

- Functional Test

- Cooling the IC while Stress Full Cycle

- Failure Analysis

- Final Test

And More…

Thermal Shock – Thermal Shock – Test Semiconductor – Temperature Cycling Test – Temperature Characterization

Temperature Simulation Test System

ThermalAir Temperature Simulation Test Systems use a direct temperature-controlled stream of hot or cold air to provide a precise thermal environment for temperature testing, thermal conditioning and test cycling of electronic and non-electronic assemblies and sub-systems. The ThermalAir Temperature system enables the test. This allows you to perform temperature simulation tests in situ, at a specific location, at your tester station, test bench or directly on the unit under test.

Design for Performance

Semiconductor IC devices on the test bench top setup in an engineering product development environment or in production.

MPI ThermalAir temperature forcing systems provide a direct thermal stream of clean dry hot and cold air directly to the part that needs to be thermal tested. Environmental stress screening, temperature conditioning, thermal shock and other temperature test requirements is that the ThermalAir temperature systems bring to the test.

Temperature Forcing, Thermal Cycling, & Thermal Shock Tests