AI’s Bandwidth and Energy Needs Redefine Thermal Testing Solutions

Author’s Note: All images used in this article were generated using AI

AI is poised to be one of the most transformative technologies in our lifetime due to its profound impact across various industries and its potential to profoundly alter lives on a global scale.

Currently, statistics indicate that end users of platforms such as ChatGPT are predominantly between 18 and 25 years old and increasing in age. However, this demographic represents only one aspect of AI’s broader potential. The technology has the capability to impact a much wider range of professions, from web developers and bloggers to coders. At present, its direct impact on everyday lives is limited, but AI stands to revolutionize more sectors as time progresses.

The advent of Nvidia’s architecture—most notably with the H100 and now the powerful new GB200 Grace Blackwell—has significantly expanded the potential for advanced AI applications. These cutting-edge chips deliver the hardware and software ecosystem necessary to train and deploy highly sophisticated systems across a wide range of industries. Let’s explore some of these emerging architectures and their transformative impact.

Here’s a list of notable AI chips currently under development:

Apple

-

- Baltra: In collaboration with Broadcom, Apple is developing an AI server chip codenamed “Baltra,” expected to enter mass production by 2026.

Amazon Web Services (AWS)

-

- Trainium3: AWS has announced the development of Trainium3, its latest AI chip aimed at improving AI training performance.

OpenAI

-

- Custom AI Chips: OpenAI is reportedly developing proprietary AI chipsets using TSMC’s A16 Angstrom nodes to reduce reliance on external suppliers and optimize performance for its AI models.

Arm Holdings

-

- AI Processors: Arm is setting up a dedicated AI chip division, aiming to launch its first AI processors by 2025, with prototypes expected in the spring and mass production in the fall of that year.

Cerebras Systems

-

- WSE-3: Cerebras has announced the WSE-3, its third-generation wafer-scale AI chip, designed to handle multi-trillion parameter generative AI tasks.

SambaNova Systems

-

- SN40L: SambaNova has developed the SN40L chip, focusing on high-performance AI workloads, and continues to innovate in AI hardware solutions.

These developments reflect the ongoing efforts by major tech companies to advance AI hardware, aiming for improved performance, energy efficiency, and integration into various applications.

While most of these high-end AI chips are still limited to being developed in Taiwan by TSMC, the race is on to expand high end wafer fabs outside of Taiwan, as TSMC expands to Phoenix Arizona with its new wafer facility set to come online at half way through 2025 with 4nm wafer production.And with other semiconductor manufacturers producing wafer Fabs in the US and other locations around the world, production of AI chips is not the end of the impact to adjacent Industries.

In a historic announcement, in May 2020, TSMC shared its plans to invest $12B in Phoenix, Arizona – building an advanced semiconductor manufacturing fabrication.

The Growing Demand for Data Storage, Energy, and High-Speed Connectivity in the AI Era

As AI technology advances, the demand for high-speed data processing and massive storage capacity has skyrocketed. AI models, particularly those used in deep learning and generative AI applications, require enormous datasets for training and inference. This necessity is driving a rapid expansion of data centers and storage infrastructure across the globe.

Modern AI workloads rely on high-bandwidth memory (HBM), solid-state drives (SSDs), and high-density storage solutions to handle the vast amounts of data being processed in real-time. Companies are investing heavily in next-generation storage architectures, including computational storage and ultra-fast NVMe drives, to keep up with AI’s insatiable need for data. Cloud providers and hyperscale data centers are leading this charge, integrating more efficient storage solutions to optimize AI training pipelines and minimize latency.

Amazon spending $650 million for data center in Luzerne County

However, with greater storage and data transfer speeds comes a parallel increase in energy consumption. AI data centers require immense power to sustain operations, and as workloads scale, so does the energy demand. The industry is seeing a push for greener solutions, including energy-efficient GPUs, liquid cooling technologies, and AI-optimized power management systems. Yet, no matter how efficient AI processors and storage solutions become, the unavoidable reality remains: energy consumption generates heat, and effective thermal management is crucial for maintaining system reliability and performance.

The Rising Need for High-Speed Fiber Optic Transceivers

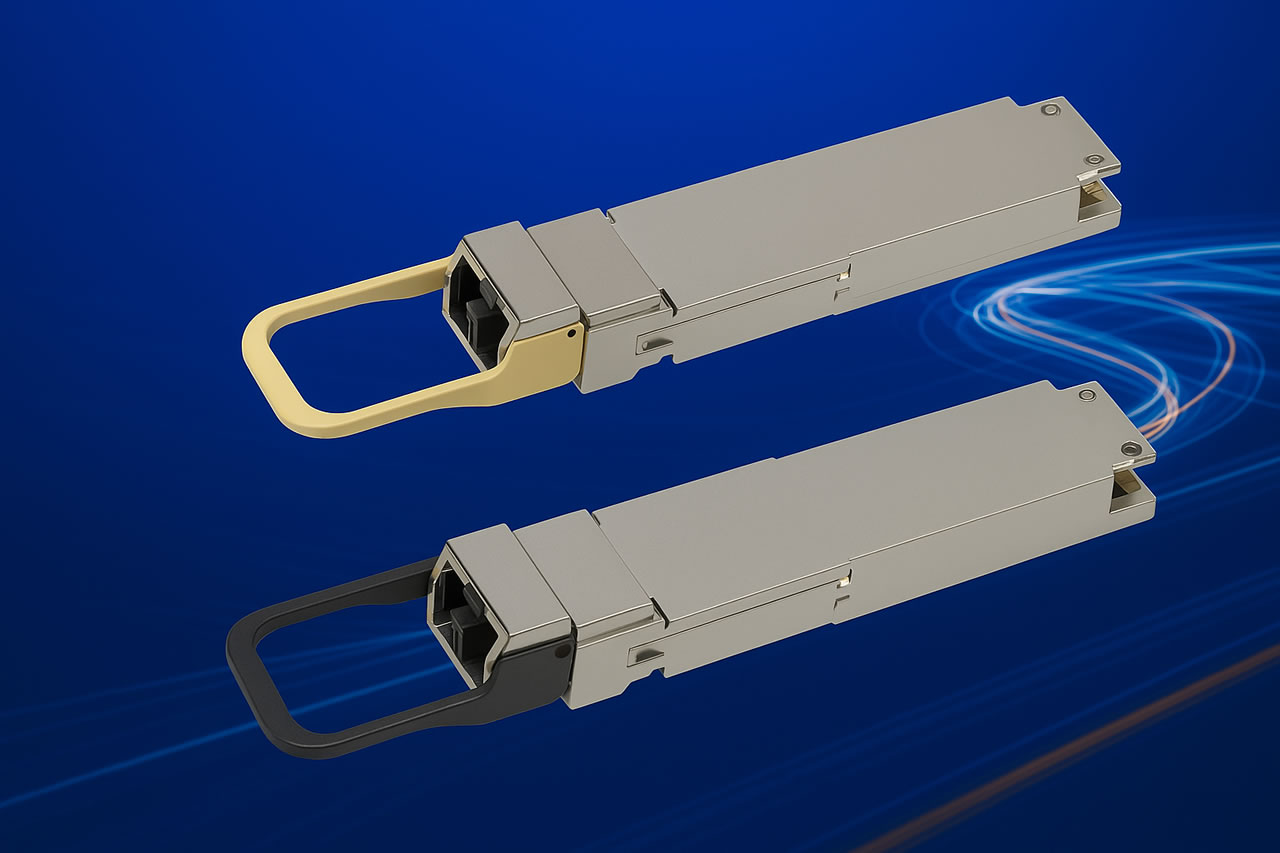

Beyond storage and power, AI’s rapid growth is also driving an unprecedented need for ultra-fast data transfer speeds. As data centers scale up their processing power, traditional network infrastructure struggles to keep pace. This has led to a surge in demand for high-speed fiber optic transceivers, particularly 400G and 800G components, which are critical for handling the massive bandwidth requirements of AI workloads.

Fiber optic transceivers play a vital role in enabling fast, low-latency data transmission across cloud networks, high-performance computing (HPC) environments, and AI training clusters. The transition from 100G to 400G/800G networking is already underway, with leading tech companies and data center operators investing in next-generation optical networking solutions to keep up with AI-driven traffic. These high-speed transceivers operate at incredibly high power densities, generating significant heat and requiring precise thermal management to ensure consistent performance and longevity.

The use of renewable energy sources, such as solar and wind power, is becoming increasingly important in meeting the high energy demands of data centers. Companies are exploring different strategies, including building their own data centers in areas with abundant renewable resources or investing in technologies that allow for on-site power generation.

Efficiency improvements, such as better cooling systems and optimized hardware designs, are also crucial in reducing energy consumption. ARM-based specialized processors, which prioritize power efficiency over performance, are gaining popularity due to their ability to run AI models at a fraction of the energy required by traditional x86 processors.

While there is progress being made, the rapid growth in AI usage presents ongoing challenges that will require continued innovation and collaboration across the industry. It’s essential for companies and governments alike to work together to develop sustainable solutions that support the growing demand for AI while minimizing environmental impact.

The world of fiber optics continues to evolve at an extraordinary pace, with new advancements in speed and form factors emerging every year. This constant innovation has shaped the industry, pushed boundaries and enabled more efficient, scalable networks.

Optical transceiver technology has come a long way from its early days. Initially, networks relied on 100Mbit and 1G solutions, with 10G being a high-cost, niche offering. Fast forward to today, and we now see 800G transceivers deployed on advanced form factors like OSFP and QSFP-DD, while 100G solutions deliver reliable performance over longer distances. Wavelength Division Multiplexing (WDM) has also become a central focus, driving greater capacity and efficiency in modern networks.

In today’s fast-paced technological landscape, where innovation drives progress across various industries, one area that stands out in both significance and complexity is temperature testing. This indispensable process ensures that products function reliably under diverse environmental conditions, from extreme cold to intense heat. The industry leaders at MPI Thermal have consistently been at the forefront of advancing these systems, making them more efficient, versatile, and user-friendly.

A Glimpse into MPI Thermal’s Legacy

MPI Thermal, a pioneer in localized temperature inducing systems, has revolutionized how products are tested for environmental stress conditions. Their flagship product, the TA-5000A, exemplifies their commitment to innovation. Designed with an advanced architecture, this system offers unparalleled performance, capable of achieving temperature testing ranges from -80°C to +225°C with extraordinary precision and stability. Moreover, its unique features, such as continuous air flow up to 25 SCFM at extreme temperatures and frost-free operation, ensure that the most demanding test conditions can be met.

The Challenge of AI Chips: A New Frontier in Thermal Testing

As artificial intelligence (AI) technology continues to advance, so do the demands on testing systems. Modern AI chips are pushing the boundaries of what is possible in terms of power meaning high power devices in many cases dissipating 1000 watts over traditional semiconductor chips. Testing methods may not be sufficient for these new extremes, necessitating specialized solutions.

Choosing MPI Thermal: The Right Partner for Your Temperature Testing Needs

MPI Thermal’s dedication to innovation and customer satisfaction makes them the ideal partner for any organization that requires reliable and efficient temperature fortcing solutions. Their commitment to excellence is evident in their extensive range of highly flexible products, which cater to a broad spectrum of industries and applications. Whether you’re testing cutting-edge AI chips or more traditional electronic components, MPI Thermal has the tools and expertise to ensure that your products meet the highest standards by bringing temperature directly to the test application in the lab or on the production floor.

Adapting to Diverse Testing Needs with Flexibility & Reusability

MPI Thermal’s advanced temperature cycling systems are engineered to provide exceptional flexibility, allowing seamless adaptation to devices and components of various shapes and sizes. Selecting the right system is critical for optimizing your thermal testing process, ensuring reliable and precise results across a broad range of applications.

A solid grasp of MPI Thermal’s comprehensive temperature inducing and cycling solutions—including ThermalAir stream systems, test chambers, and air chillers—lays the foundation for developing an efficient, accurate, and customized thermal testing approach. Choosing the appropriate thermal testing equipment directly enhances the consistency and quality of test outcomes, leading to improved performance and reliability of components and assemblies. These refined testing methodologies play a vital role in meeting stringent industry standards, ensuring products perform as expected in real-world conditions.

Moreover, MPI Thermal’s temperature cycling test solutions stand out for their adaptability. Unlike conventional chambers designed for specific, singular applications, MPI Thermal’s systems—especially the TA-5000 and TA-3000 series—are built for versatility. Their rapid temperature cycling capabilities offer precise control over ramp rates, soak times, and thermal cycling, effectively replicating the performance of larger environmental test chambers while catering to localized testing needs. With a temperature range spanning from -80°C to +225°C, these systems provide a reliable, repeatable, and efficient solution for diverse thermal testing scenarios.

To view the complete product line of MPI Thermal ‘s Temperature Testing Solutions…

Author’s Note: All images used in this article were generated using AI

-

AI’s Bandwidth and Energy Needs Redefine Thermal Testing Solutions

AI’s Bandwidth and Energy Needs Redefine Thermal Testing Solutions Author's Note: All images used in this article were generated using AI AI...

-

Thermal Shock vs. Thermal Cycling Test

Thermal Shock vs. Thermal Cycling Test: Understanding the Different Types of Reliability and Accelerated Life Testing Thermal shock tests and...

-

AI Shaping the Future of Optical Transceivers in Telecommunications, Data Centers, and AeroSpace

As artificial intelligence technology advances, it increasingly relies on three major elements: large-scale models that simulate complex processes,...

-

Environmental Temperature Test Challenges In Lidar Devices, Sensors And Radar Technologies

As the demand for autonomous vehicles escalates, the Advanced Driver Assistance Systems market is experiencing rapid growth. In this expansion,...

-

Thermal Test Solutions for Aerospace and Defense Applications: Discover MPI Thermal’s Advanced Technologies

Explore MPI Thermal’s industry-leading thermal solutions, specifically engineered to meet the rigorous demands of aerospace and defense...

-

Diving Deep: Uncovering the Secrets of Semiconductor Reliability Testing in Extreme Environments

In today’s rapidly advancing technological landscape, the reliability of semiconductor components is more crucial than ever before. As the demand...

-

Low Temperature Test Chambers: Extreme Cold Environment Simulation

Low temperature test chambers are critical tools for evaluating product performance and durability in extreme cold environments. These chambers...

-

Small Temperature Test Chambers for Precise and Efficient Rapid Thermal Cycling Test

Small Temperature Test Chambers for Precise and Efficient Rapid Thermal Cycling Test Introduction to Small Temperature Test Chambers Small...

-

Advanced Thermal Test Solutions in Automotive Electronics: An Overview of Environmental Temperature Testing Technologies

In a world where the automotive industry is at the cusp of a transformative phase, rapidly transitioning towards green technologies and a heightened...

-

Unlocking the AI Potential: Advanced Temperature Testing for Critical Electronics

Artificial Intelligence (AI) has rapidly become a driving force in our modern world, revolutionizing industries and enhancing our daily lives in...

-

Advanced Thermal Cycling Test Equipment for PCB Reliability Test

Cutting-Edge Technology for Accurate Thermal Testing. In the evolving landscape of product testing, the use of advanced thermal cycling test...

-

The Indispensable Role of Test Chambers in Battery Testing

The fast-paced world of technology and innovation has rendered battery testing an integral component of product development. Test chambers,...