Fiber Optic Temperature Test Applications

Fiber Optic Transceiver manufacturers test these devices to assure optical transceivers circuits work at certain temperatures. This is to guarantee reliability of these high speed fiber optic transceivers used within the communication high speed network and data center industries.

-80°C / +225°C

ThermalAir Systems for SFP Fiber Optic Transceiver

The small form-factor pluggable (SFP) is a compact, hot-pluggable network interface module used for both telecommunication and data communications applications. … SFP transceivers exist supporting SONET, Gigabit Ethernet, Fibre Channel, PON, and other communications standards.

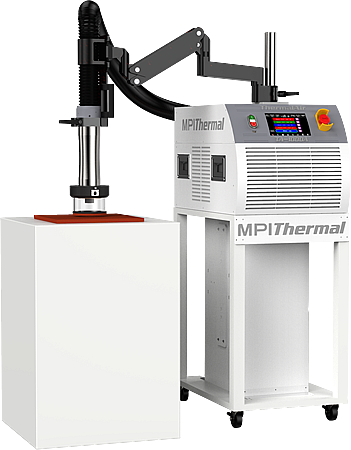

MPI ThermalAir stream systems meet the temperature test standards for fiber optic 25G, 40G, 100G, 400G, 800G and 1.6T optical transceivers. Our ThermalAir products provide uniform methods to generate hot and cold temperature for fiber optic transceivers common temperature test range of -40°C to +90°C.

MPI Thermal TA-1000 systems control temperature for testing fiber optic transcievers and other fiber optic compaonents. This assures your parts are suitable for use within industrial, commercial and consumer electronic systems. These include basic temperature tests to determine characteristics of these Optical Transceivers / Laser devices over temperature.

Thermal Tuning

Fiber-optic transceivers must operate with absolute stability across rapidly changing environments and tight wavelength requirements. Minute shifts in temperature can alter laser wavelength and signal integrity, so manufacturers replicate real-world temperature stressing —heat spikes and cold shock—to validate long-term performance. By precisely controlling and cycling temperatures, engineers can fine-tune components to maintain optimal optical alignment and minimize bit-error rates.

This need for accurate, repeatable temperature conditioning is why the MPI ThermalAir TA-1000 Series is an integral part of the thermal tuning and charactization test process.

Temperature Cycling Optical Transceivers – Accelerated Stress Testing – Temperature Test Chambers – Temperature Conditioning – Temperature Cycling Optical Transceivers

Meeting the Demands of AI-Driven Data Centers with Optical Transceiver Validation

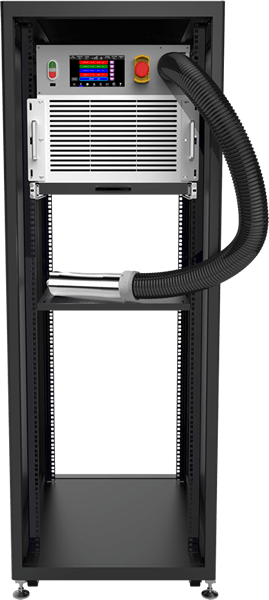

As the industry races to build next-generation hyperscale infrastructure to support AI workloads, the performance of optical transceivers has become a mission-critical focus. These high-speed components are essential to the interconnects between compute nodes, including thousands of GPUs, and must perform reliably under dynamic and demanding thermal conditions. One of the most pressing technical challenges is interoperability—ensuring transceivers not only meet specification in isolation but also maintain stable, high-speed links when integrated into complex, real-world systems. This calls for advanced thermal validation both during development and again at system-level integration. In our recent demonstration, a compact, rack-mounted temperature test system was used to perform thermal stress testing on transceivers—directly replicating the heat profiles expected in future AI data center environments.

Temperature Forcing System

MPI ThermalAir temperature forcing systems provide a direct thermal stream of clean dry hot and cold air directly to the part that needs to be thermal tested. In the lab or on the production floor, ThermalAir Series provide unparalleled thermal stress testing capabilities for scientist and engineers.

The ThermalAir system allows you to generate very precise controlled temperature for simulation test in Thermal Shock, Temperature Conditioning, Stress Screening, Temperature Cycling and more. Thermal test processes can be accomplished with our ThermalAir system. Ramp, Cycle, Dwell and Soak times are fully programmable with a touch of a button.

Thermal Testing Optical Transceivers – HALT/HASS – Temperature Test Chambers – Thermal Profiling – Testing 40G Optical Transceivers | HALT Testing

Temperature Cycling Test Equipment

The design challenges go well beyond simply delivering processing power and high-speed data transfer. Design engineers must also safely manage heat generated by those processes in the confines of tight vehicle packaging requirements, as well as ambient and cold temperature fluctuations, while adhering to stringent safety and reliability standards of the electronics industry.

Environmental Stress Testing

Environmental stress conditions such as radiation exposure, temperature extremes, vibration, and dirt encountered by the military, on factory floors, and under the hoods of automobiles, these semiconductor devices need to keep working. To assure quality and reliability of electronic devices, semiconductor manufacturers need to simulate harsh environments during the engineering and production test stage. This is why the MPI Thermal TA-5000 Series ThermalAir temperature test products are part of the test.