Specification Features & Benefits

- Ultra Cold Temperatures maintained at 50&60Hz

- Dual Touch Screens Front Panel & Thermal Head

- Plug-in anywhere from 200~250VAC, 1Ø

- ECO Smart DC system for up to 50% energy saving

- No voltage configuration to use at different locations

- Versatile Boom & Stand – Extended reach standard

- SSD for thermal file management and data logging

- Control Heated dry air purge for frost free operation

- One touch Temp Cycle, Ramp, Soak and Dwell

- Ultra low audible noise for quiet engineering lab use

System Performance

- Airflow: High capacity 10 l/s (20 scfm) continuous airflow optimizes temperature transition rate and throughput.

- Typical Temperature transition rate: -55° to +125°C: approximately 10 seconds +125° to -55°C: approximately 10 seconds

- Temperature Control: Environment Air or External DUT sensing directly at the DUT case to ±1.0°C

- Temperature control Sensor Ports: Type T or Type K thermocouple, and 100 ohm RTD

- Temperature set, display and resolution: ±0.1°C

- Temperature Accuracy: 1.0°C ( calibrated to NIST standard)

- Remote interface ports: Four: IEEE-488, RS232C, SOT/EOT/SFF, And Ethernet, 4 USB-Type A, 1 USB-Type B, VGA, LAN, PLUS Auto Start Test & End of Test for automatic temperature cycling Hot-Cold-Amb. All this makes for simple control and service ability.

Temperature Cycling Test Chambers

MPI Thermal Test Chambers meet the demand for localized environmental temperature testing.

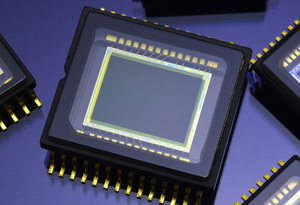

The ThermalAir temperature test equipment is used for thermal test of semiconductor, automotive sensors,fiber optic components, microwave, hybrids, MCMs, PCBs or any type of electronic and non-electronic parts. Our temp cycle systems connect to your test setup to bring temperature test capabilities directly to your bench top or test station.

Temperature Cycling Chamber Clamshell Model